Following the appearance of plastic 3D-printing technology the field of architecture is on the brink of a technological revolution with traditional 3D architecture design methods radically transformed. Not just a small advance over current procedures, this revolutionary force questions traditional methods of architectural visualization, prototype building, and construction planning.

Transforming Design Communication and Visualization

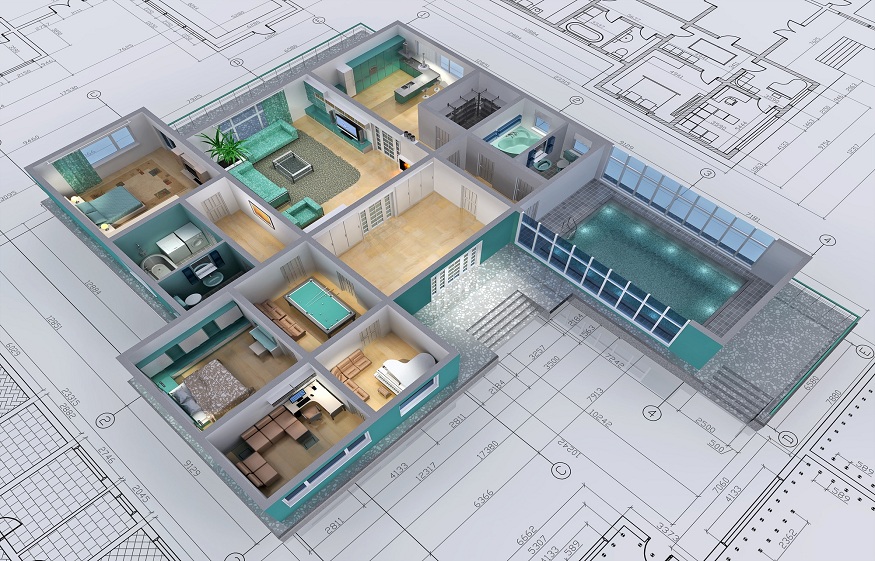

3D plastic printing has radically changed architects’ ability to communicate intricately conceived spatial ideas to anyone from customers to stakeholders to construction team members. Consequently, though important, traditional two-dimensional drawings and computer simulations often fail to adequately describe complex architectural space relationships and the heart of the project. 3D-printed physical models help fill the communication gap by providing the ability to be held, touched, and viewed from multiple angles, something that is impossible with digital models.

Using today’s plastic printing technology, available with the highest accuracy now possible, architects can produce beautifully detailed scale models with every last detail of flowing curves and complex geometric patterns. These models, which can be effective communication tools for design concepts in client presentations, may help stakeholders understand design concepts throughout the design development process and provide more knowledgeable comments.

How to make this design iteration process faster?

Since it’s also fast and incredibly accessible, plastic 3D-printing has cut down the time it takes to iterate on a design. Architects can create dozens of quick design iterations in days rather than weeks, experiment with several space arrangements, explore several aesthetic treatments, and so forth. Ultimately, this higher level of acceleration drives better-resolved architectural 3D design solutions through more thorough design exploration and refinement.

The potential to generate tangible prototypes in a well-timed way promotes the exploration of intricate geometries which could in any other case be deemed too high priced or hazardous to research the usage of traditional model-making strategies. A developing number of architects are the usage of parametric layout strategies, wherein mathematical equipment produces a number of layout opportunities that can be fast prototyped and assessed in the use of bodily models.

Strengthening Spatial and Structural Analysis

3D-printed physical models made of plastic are useful resources for spatial research and structural examination. Hands-on study of printed models allows engineers and architects to analyze load distribution patterns, spot any structural issues, and optimize building systems. This tactile method of structural knowledge offers insights that may be missed in solely computer approaches and enhances digital analytical tools.

The capacity to print models with diverse colors and material qualities enables in-depth examination of various building systems and components. To provide comprehensive analytical tools that support interdisciplinary cooperation and decision-making, structural elements, mechanical systems, and circulation patterns can all be printed in different colors.

Restructuring Approval and Client Engagement Procedures

Plastic 3D-printing affects client relations and project approval procedures in addition to the design studio. In public consultations, regulatory review procedures, and municipal planning meetings, physical models made with 3D printing have shown especially good results. Accurate physical representations, as opposed to abstract drawings or computer renderings, are more effective in helping city planners, community people, and regulatory officials comprehend proposed developments.

Because of these improved communication skills, approval procedures have become more efficient, and miscommunications that frequently occur during project review cycles have decreased. Examining physical models helps stakeholders spot possible issues more easily, which facilitates more fruitful conversations and expedites the resolution of design problems.

Facilitating Intricate Geometric Research

Architects may now create without many of the geometric limitations that were previously imposed by plastic 3D-printing. Modern joining systems, sophisticated lattice structures, and complex curved surfaces that would be very costly or difficult to construct using conventional processes may now be readily prototyped and tested. This flexibility has inspired architects to push the limits of architectural expression and experiment with more daring formal languages.

When it comes to creating models of structures with intricate geometries, including those that use fractal patterns, mathematically generated forms, or biomimetic design concepts, the technology is very good. These geometric investigations frequently result in new building design methodologies and advancements in real construction methods.

Improving Multidisciplinary Cooperation

3D printed models’ physical quality has enhanced cooperation between contractors, engineers, architects, and other project participants. During team meetings, physical models are used as shared reference points, which facilitates better communication between members of various professional backgrounds and specialties. Using physical models helps team members better spot coordination issues, clarify spatial links, and point to specific elements.

Because perfect coordination between the structural, mechanical, and architectural systems is crucial during the construction documentation phase, this improved collaboration has been very beneficial. Physical models assist in spotting possible disputes before they develop into expensive field problems.

Promoting Eco-Friendly Design Principles

Through the reduction of waste related to conventional model-making materials and techniques, plastic 3D-printing has helped to promote more environmentally friendly design techniques. Unlike conventional architectural models, which should be stored and ultimately disposed of, virtual layout files may be stored and reprinted as needed.

Implications for the Future and Upcoming Patterns

Its influence on construction modeling and architectural design is expected to grow as plastic 3D printing technology develops. Models that better capture the material complexity of real structures could be produced thanks to newly developed multi-material printing technologies. The integration enables the opportunity for the development of hybrid physical-digital modeling techniques that knit together the strengths of virtual and augmented reality technologies.

The technology behind 3D printing has been democratized so now smaller architectural firms and academic institutions can utilize advanced modeling skills, as this resource could spark a newer and greater level of creativity in design processes and approaches.

Conclusion

Plastic 3D printing has already transformed construction modeling and architectural design and that role will become more prominent with further advancements in technology and deepening availability. This is more than just a simple set of technical advancements – new perspectives on design, communication, and teamwork in the architectural profession are all part of the shift. As long as architects are exploring the possibilities of contemporary technology, the lines between the digital and physical world of design are starting to blur, ushering new paths for architectural expression and creation.