The food and beverage industry is constantly evolving, driven by an insatiable desire for innovation and efficiency. One often overlooked but crucial component behind this transformation is the stainless steel gear pump. This unsung hero plays a vital role in optimizing processes, ensuring product quality, and ultimately revolutionizing the industry. In this blog post, we will explore how stainless steel gear pumps are making waves and why they’re indispensable for manufacturers. You’ll discover how these pumps streamline operations, improve hygiene standards, and offer reliability that stands the test of time.

What Are Stainless Steel Gear Pumps?

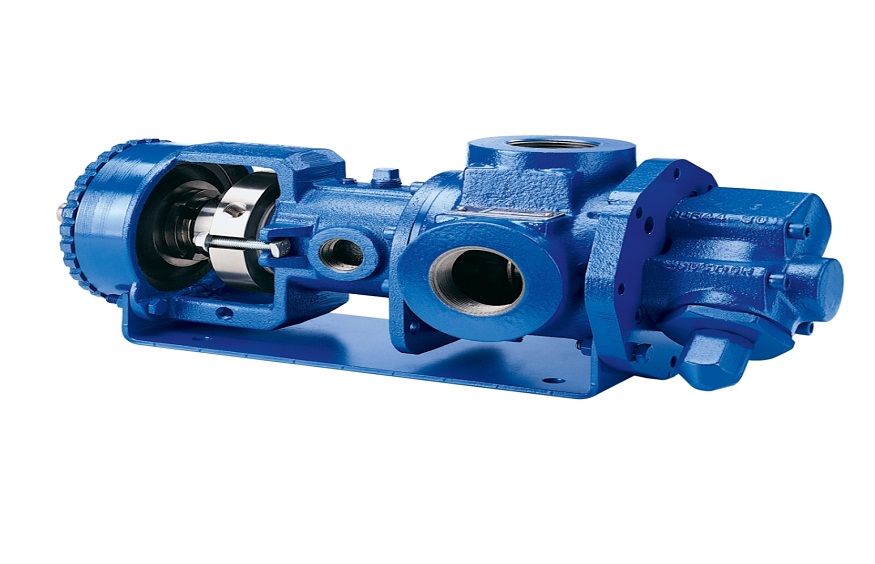

To fully appreciate their impact, it’s essential to understand what stainless steel gear pumps are. These pumps are mechanical devices designed to move liquids by using the meshing of gears to create a smooth, continuous flow. They come in various configurations, but their core function remains the same—efficiently transferring fluids from one point to another. The use of stainless steel as the primary material ensures durability and resistance to corrosion, making them ideal for the food and beverage industry.

Stainless steel gear pumps excel in handling viscous liquids, which is common in food production. Their robust construction allows them to handle thick sauces, syrups, and even chunky mixtures without clogging or losing efficiency. This capability is a game-changer for manufacturers looking to maintain consistency in their products. Furthermore, the precision engineering behind these pumps ensures that there is minimal product wastage, a crucial factor in maximizing profitability.

Another significant advantage is their adaptability. Stainless steel gear pumps can be customized to fit specific production needs. Whether it’s adjusting the flow rate or pressure, these pumps provide the flexibility necessary to meet a wide range of operational requirements. Their versatility makes them a valuable asset in any production line, capable of handling different tasks with ease.

Enhancing Efficiency in Production

Efficiency is the backbone of modern manufacturing, and stainless steel gear pumps are at the forefront of driving this efficiency. Their design allows for continuous operation with minimal downtime, ensuring that production lines operate smoothly and without interruption. This seamless performance translates to faster processing times, increased output, and ultimately, higher profits.

One of the primary ways these pumps enhance efficiency is by reducing energy consumption. Their precise engineering minimizes friction, allowing for smooth and uninterrupted flow of liquids. This efficiency not only saves energy but also reduces wear and tear on the equipment, extending its lifespan and lowering maintenance costs.

In addition to energy savings, stainless steel gear pumps offer improved accuracy in fluid transfer. Their consistent flow rate ensures that the exact amount of product is delivered every time, reducing variations and ensuring that each batch meets the desired quality standards. This precision is particularly crucial in industries where consistency is key, such as food and beverage production.

Maintaining Hygiene and Safety Standards

In the food and beverage industry, hygiene is paramount. Stainless steel gear pumps play a vital role in maintaining stringent hygiene and safety standards. The use of stainless steel, a non-reactive and easy-to-clean material, ensures that these pumps meet the highest sanitary requirements.

The design of stainless steel gear pumps minimizes areas where residues can accumulate, reducing the risk of contamination. Furthermore, their smooth surfaces and lack of crevices make them easy to clean and sanitize, ensuring that they meet the rigorous standards set by regulatory bodies. This cleanliness is critical in preventing bacterial growth and ensuring product safety.

Another safety benefit is their robustness. Stainless steel gear pumps are designed to withstand high temperatures and pressures, ensuring that they can handle the demands of food and beverage production without compromising safety. This durability provides peace of mind to manufacturers, knowing that their equipment is reliable and safe.

Reliability and Durability

When it comes to manufacturing, reliability is non-negotiable. Stainless steel gear pumps are renowned for their durability and ability to withstand the harsh conditions of food and beverage production. Their robust design ensures that they can handle the demands of continuous operation, providing manufacturers with a reliable solution that minimizes downtime.

The use of stainless steel in gear pump construction ensures that they are resistant to corrosion, a common issue in environments where moisture and chemicals are prevalent. This resistance not only extends the lifespan of the pumps but also ensures that they continue to perform optimally, even in challenging conditions.

In addition to their corrosion resistance, stainless steel gear pumps are built to handle high pressures and temperatures. This capability makes them suitable for a wide range of applications, from handling hot liquids to working in high-pressure environments. Their versatility and durability make them a cost-effective solution for manufacturers looking to maximize their return on investment.

Versatile Applications in Food and Beverage

Stainless steel gear pumps are incredibly versatile, finding applications across a wide range of food and beverage processes. From dairy production to beverage bottling, these pumps are essential for ensuring smooth and efficient operations. Their ability to handle a variety of liquids, from thin juices to thick sauces, makes them a valuable asset in any production line.

In the dairy industry, stainless steel gear pumps are used to transfer milk, cream, and yogurt efficiently. Their precision ensures that the right amount of product is delivered, reducing wastage and ensuring consistent quality. Similarly, in beverage production, these pumps are used to handle a variety of liquids, ensuring that each bottle is filled accurately and efficiently.

Their versatility extends to handling delicate products as well. Stainless steel gear pumps can handle products with particulate content, such as fruit pieces in sauces or soups, without compromising the integrity of the product. This ability to handle a range of products makes them an indispensable tool for manufacturers looking to diversify their offerings.

Cost-Effective Solutions

Cost-effectiveness is a critical consideration for any manufacturer, and stainless steel gear pumps offer a compelling solution. Their durability and low maintenance requirements translate to reduced operational costs, making them an economical choice for food and beverage manufacturers.

The energy efficiency of these pumps further contributes to cost savings. By minimizing energy consumption, manufacturers can reduce their utility bills, a significant advantage in an industry where margins can be tight. Additionally, the precision and accuracy of stainless steel gear pumps reduce product wastage, maximizing profitability.

Furthermore, their versatility means that manufacturers can use a single type of pump across multiple applications, reducing the need for specialized equipment. This flexibility not only simplifies maintenance but also reduces capital expenditure, making stainless steel gear pumps a smart investment for any production facility.

The Future of Food and Beverage Manufacturing

The food and beverage industry is poised for continued growth, driven by increasing consumer demand and technological advancements. Stainless steel gear pumps are at the forefront of this transformation, offering a reliable and efficient solution for manufacturers looking to stay competitive.

As the industry evolves, manufacturers must adapt to changing consumer preferences and regulatory requirements. Stainless steel gear pumps provide the flexibility and reliability needed to meet these challenges head-on. Their ability to handle a wide range of applications ensures that manufacturers can continue to innovate and meet the demands of the modern consumer.

In conclusion, stainless steel gear pumps are revolutionizing the food and beverage industry, driving efficiency, maintaining hygiene standards, and offering reliability that manufacturers can count on. By investing in this essential technology, manufacturers can position themselves for success in an increasingly competitive landscape.

For manufacturers looking to stay competitive, investing in stainless steel gear pumps is a smart move. These pumps offer the efficiency, reliability, and versatility needed to meet the demands of the modern food and beverage industry. To learn more about how stainless steel gear pumps can benefit your production facility, explore our range of products or contact our team for expert advice.